Clay extruders are an efficient way to make hollow forms, coils, and other shapes. They are basically tubes with a die attachment and a lever, and there are just enough models on the market to make it a bit confusing to choose. This guide will cover recommended models, and includes a comparison chart of all the models on the market so that you can pick the best extruder for your studio.

The models covered here will make hollow forms ranging from about 2 inches wide to 8 inches wide, although most models will extrude forms around 3 inches wide. They will also make solid coils and other shapes, and all models have blank dies that you can customize to suit your needs or some manufacturers will make custom dies. The smaller sized barrels, such as the Bailey 4” wide extruder, will be the best choice for most studios. But there are larger models and upgrade picks to consider too.

When choosing a model, consider how you will be using it. If you will mostly make solid coil, handle, or other shapes, stick with a 4” wide model as that will be easiest to manage. If you will be making mostly hollow forms, any size model will be relatively easy to extrude; just choose a model that will be big enough for your needs. Other options to consider are the lever style, die options, and ease of cleanup.

The North Star Big Blue Extruder, the only extruder on the market with a round “wagon wheel” handle. It’s wall mounted with a variety of dies.

TOP PICK

The top pick and I believe most innovative extruder on the market is the North Star Big Blue Extruder. Featuring a wagon wheel handle, it is easy to use, has a large capacity barrel, and is durable and long lasting. It’s one of the more expensive extruders (aside from powered extruders) but the size, versatility and easy of use more than compensate for the high price point. The gear system allows you to turn the handle and extrude with ease, and the barrel can hold up to 25 lbs of clay. The Big Blue extruders typically retail from around $900 to $1090.

The Bailey 4 inch extruder features a wall mount, lever handle, and interchangeable dies.

BEST FOR MOST STUDIOS

For most studios, a basic Bailey 4” extruder is a great option. The 4 inch square barrel allows you to make hollow forms up to 3 inches in diameter, but it’s not so large that it’s hard to extrude the clay. This extruder typically costs around $400 and the die kit is an additional $130. It’s one of the better options when you consider price and the die options, but drawbacks include installing the dies and that the barrel is welded to the wall mount, making clean up harder.

If you are looking for a handheld, mini extruder, or “clay gun,” check out our Handheld Extruder Guide here.

A complete review of wall mounted clay extruders follows.

Table of Contents

Top Pick: North Star Big Blue Extruder

Runner Up: Bailey 4, 5 or 9 inch extruders

North Star 4 inch extruder

Scott Creek 4 or 5 inch extruder

Brent Extruders

Other Wall Mounted Extruders

Powered Extruders

Extruder Tips

Extruder Comparison Chart

Summary

Top Pick: North Star Big Blue Extruder

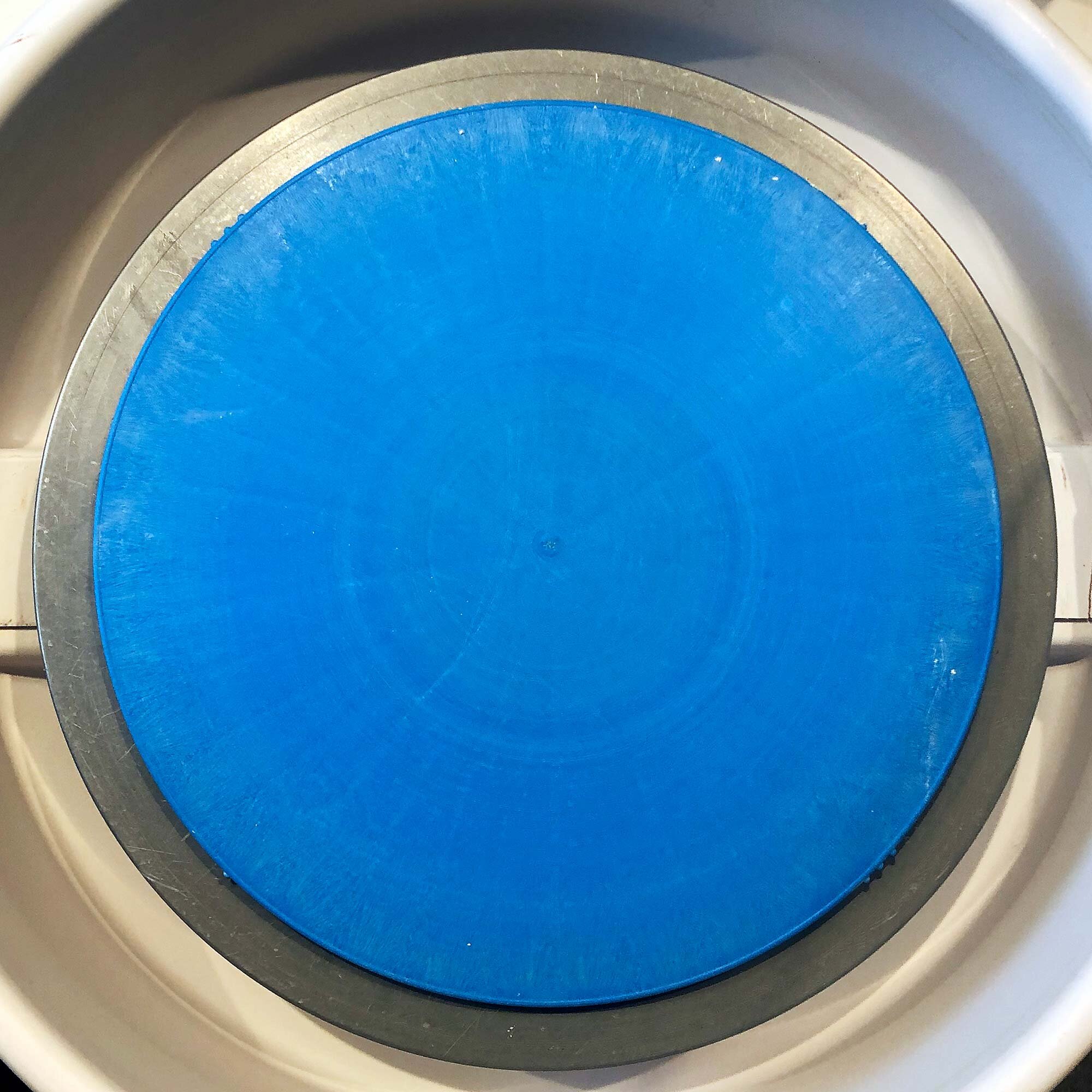

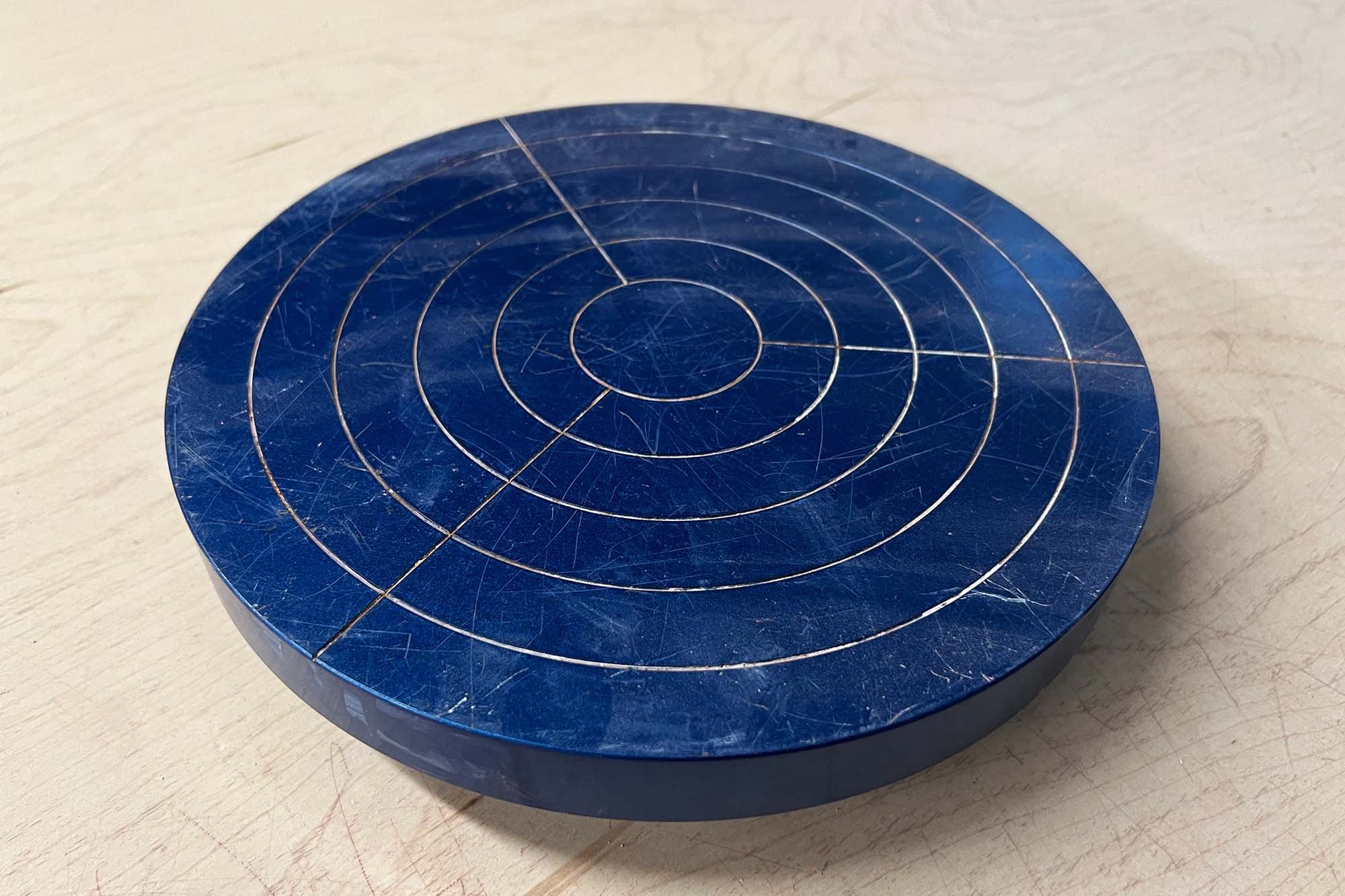

The North Star Big Blue Extruder.

The North Start Big Blue Extruder combines a big barrel capacity with an easy-to-turn wagon wheel handle and a wide selection of dies. It does cost a premium, typically $900 to $1090, but the size and versatility makes it a wonderful addition to any studio.

The Big Blue has a 6 x 6 x 12 inch tall aluminum barrel that will hold up to a full 25 lb bag of clay. The dies can extrude up to a 4.5 x 4.5 inch wide hollow form, and the dies are a sturdy, hard plastic.

To use the extruder, the die and bottom brace are attached to the barrel with two hex screws. The dies have helpful channels to lock into place. Then, the barrel is filled with clay, and this whole unit is slid up and in and attached to the machine. On one hand, this is an advantage as the dies and clay can be added at a workbench, but the drawback is that you have to move up to about 30 lbs in to place and secure it on the ledge “lip” that will hold the barrel securely. Overall, I find it easy to use, but you want to make sure that you don’t drop a clay-filled barrel on your feet so a shelf or stool underneath can help.

The wagon wheel handle and rack and pinion gears are the real selling point for me, as it makes it much easier to extrude large amounts of clay for extra long tubes and coils. Every other extruder on the market uses some form of a lever handle, which can be dangerous if left sticking out into your space, and they can be hard to pull down. The wagon wheel handle is also relatively compact, or at least it doesn’t stick out into your space.

The Big Blue Extruder is not cheap, typically priced anywhere from $900 to $1090, and the dies cost about $40 each. But, it’s an amazing machine that if properly cared for, will work for decades. I simply keep it clean and add some grease to the gears from time to time.

Runner Up / Best for Most Studios: Bailey 4”, 5” or 9” Extruders

The Bailey 4 wall mounted extruded with a 4” barrel.

Bailey makes a great line of clay extruders that are well built and available at a lower price point than the North Star Big Blue. The Bailey models feature a barrel welded to the wall mount, dies that attach with a brace, and a plunger with a lever that slides up and down the pole.

The models include a 4” barrel, a 5” barrel, and a much larger 9” barrel. The 4” and 5” models are available in mild steel or stainless steel—you’ll want to go with stainless if you are using porcelain and are worried about rust. Bailey also makes two sizes of die kits, one kit fits both the 4 and 5 inch barrels, while there’s a larger kit for the 9” extruder. There’s also an extension kit that adapts the small dies to the bigger barrel. If you want, there’s also an upgraded powered version with a variety of stands and other tools suitable for a production studio. When considering the Bailey models, keep in mind the cost of the die kit because the models only come with one coil die and two blank plates, so you’ll definitely have to buy dies.

Overall, it’s a flexible system that is well engineered and is suitable for a wide variety of studios. On the 4 and 5 inch models, the die is attached to the bottom of the barrel via a brace with swinging arms, which are then screwed tight with wing nuts. Then, clay is added to the barrel, the plunger is inserted and you pull the lever to extrude the clay. The 9” model only differs in that the die is held on with C clamps. On all models, hollow form dies are held in place with a cross bar—it screws on to the dies so if you are frequently using multiple hollow forms, plan to buy extra cross bars to save time.

The Bailey 9” extruder can make hollow forms up to 8” in diameter.

It’s a bit cumbersome to attach the dies but once in place, these are easy to use. One drawback is the Baileys are harder to clean as the barrel is mounted to the wall. If you have time, let any clay inside dry completely, scrape it out, and then wipe clean with a large sponge. It’s helpful to oil moving parts and the dies as needed, to prevent rusting. It’s also easy to lose the wing nuts with the Bailey models, so keep track of those! If you are doing a serious amount of extruding, you’ll also want to research the various expansion boxes and powered models that Bailey makes.

Understanding the models

The 4” models will hold 11 lbs of clay. The 5” will hold 17 lbs of clay. The die kit is the same for both of these models, ranging from 2 to 3” diameter for hollow forms. The 5” models allow you to extrude longer or more forms, but it may be harder to pull the lever with the increased volume of clay.

Standard 4” typically costs between $310 and $390, while the Stainless 4” ranges from $345 to $435, and the die kit costs about $130. The Standard 5 typically retails for $340 to $425. There is also a Stainless 5 option, but it’s only available with a custom build.

The 9” model will hold up to 29 lbs of clay andtypically retails for between $520 and $650, and the die kit for this model costs around $150.

Overall, for most studios I would recommend the 4” model as that will be the easiest to extrude and 11 lbs of clay will result in a decent amount of extruded forms.

North Star 4” Stainless Extruder

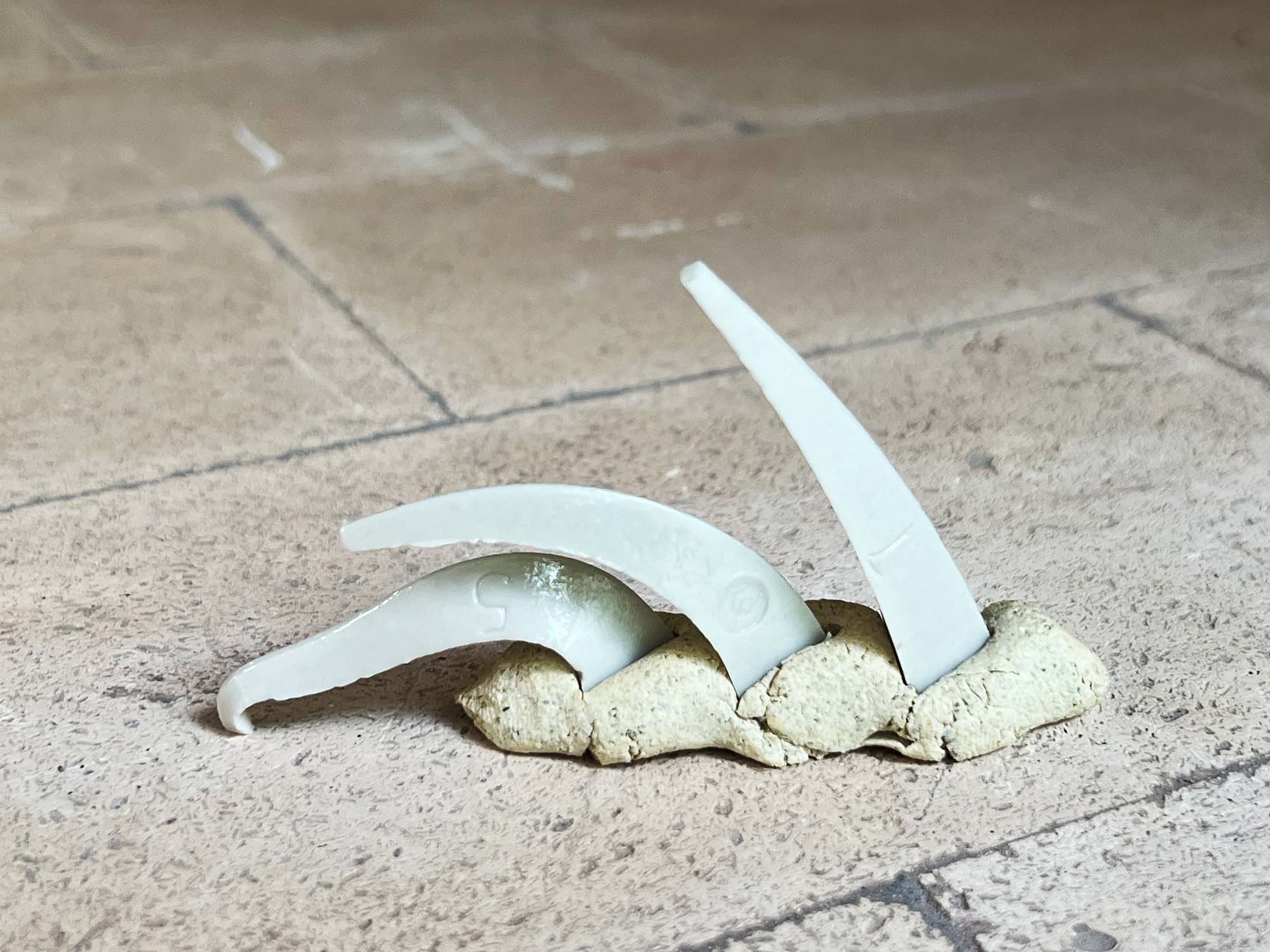

The North Star 4” Stainless extruder comes with the 3 dies picture and the lockout plate.

In addition to the Big Blue Extruder, North Star makes a lever-style extruder with a 4” wide steel or upgraded stainless barrel. The lever is fixed, as opposed to the sliding style of the Bailey, making it a safer to operate. (There’s a chance of pinched fingers with the Bailey if you’re not careful). There’s also a lever extension that will help make extruding easier. The trade off with the fixed lever is the barrel is smaller, holding just 8 to 9 pounds of clay. But, this should still extrude hollow forms that are 15 to 18 inches tall or more, you’ll just have to reload the barrel a bit more frequently.

The North Star 4” Standard Extruder is made with mild steel.

The compact size, fixed lever, simplicity of use, and optional stainless upgrade make this a great extruder for most studios. The steel barrel typically retails for around $370, while I’ve seen this stainless anywhere from $409 to $519, and the extruder does come with 4 coil dies. You will need to purchase the hollow die set separately.

Another consideration with either of these models is that there is a 6” expansion box that allows you to use the same dies as used in the Big Blue Extruder. If you wanted to keep open an upgrade possibility, this is the model for you.

The Stainless option exists for those who work in porcelain and want the smallest possibility of rust possible. But if you keep your extruder clean and maintained, it should stay rust free.

This extruder is available at many clay suppliers or direct from North Star.

Scott Creek 4” and 5” Extruders

The Scott Creek 4” Extruder

Scott Creek makes a 4” round barrel and 5” square barrel extruder with an interesting twist: a stair-step lever crank that you move up and down as needed. These extruders also have a great feature: a quick-release die cap to make installing and switching dies a breeze.

Both models feature an aluminum barrel, which will never rust and can be used with porcelain. The barrels also can be removed from the wall mount for easy cleaning, which is a noteworthy feature for an extruder!

All in all this is a great system. You pay extra up front for features such as the aluminum barrel and quick-release end cap, but the ease of use will more than make up that cost over traditional steel extruders.

The 4” round barrel typically costs around $400 and the dies range from $52 to $140, and the 5” square barrel costs around $440 plus the dies. There are also expansion boxes for each model and associated dies, and Scott Creek makes table mounts and and a free-standing extruder stand.

With all this great stuff (especially that quick-release cap) I still would favor the Bailey system over these because of the flexibility of using the same die sets in different Bailey models. With the Scott Creek, you are locked in to that size die, or the specific expansion box that goes with that model. But if you take a look and find that the die sets and sizes work for your needs, then by all means, get one of these extruders. It will be a workhorse and there are many positive reviews of these models.

These extruders are available at speciality ceramic suppliers or directly from Scott Creek.

Brent Extruders

The Brent HD Extruder features a removeable barrel and quick-release end cap.

Amoco Brent makes two extruders, the STD and HD, that combine a lot of the best features of other manufactures in a typical overbuilt Brent style, allowing it to take all kinds of use (and abuse) such as what you might find in an academic studio. But you will pay extra, with each model clocking in around $650 to $700. This review will focus on the HD as it has some upgrade features and can often be found for a bit less than the STD, around $650.

The Brent HD extruder has a 4” round steel barrel that will hold up to 10 pounds of clay. The barrel attaches to the wall bracket with 2 quick-release pins, making it easy to remove and clean. It also has a twist-and-turn end cap to hold dies, making it way less fussy than the Bailey extruders. Another thoughtful feature is a built-in hook to hang the end cap when not in use. Finally, it has a “clutch” lever to facilitate either raising or lowering the plunger and lever.

In addition to the wall mount, Brent makes a table mount and a mount designed to fit on a Brent slab roller. Like Brent slab rollers, this is an overbuilt workhorse that does come at a premium price. A drawback is a relatively limited selection of hollow dies. In general, all round barrel extruders just don’t have as much space and die options as a similar-sized square barrel.

If you have a Brent slab roller or love Brent products, then go with this extruder. It’s well built and has a lot of features, but for the main thing that you want an extruder to do—extrude shapes, especially hollow forms!—this extruder has limitations. But custom dies might solve your problems. For more info on this model and dies, the Brent website has the best info but you might find it for sale for less at online retailers or ceramic suppliers..

Other Wall Mounted Clay Extruders

There are a few more extruders that are on the market. But with limited availability, I’m reluctant to recommend these until they are sold at more locations and it’s clear there will be long-lasting product support from the manufacturers. But if you see features and prices that work for you, go ahead and order a whole set up.

Crackpots Extruder

The Crackpots Clay Extruder

The Crackpots Extruder is a straight forward, fixed lever, round barrel extruder with a variety of interesting die options, especially from aftermarket die vendors on eBay. It typically retails for $199 or less, making it one of the most affordable wall-mounted extruders.

Find it at oldsashartisans.com.

Clay Master 4” Extruder

The Clay Master extruder is available at a few ceramic suppliers. It’s unclear who manufacturers this device and the die options are limited. But, other square 4 inch dies will most likely work with this extruder. It has a fixed or “anchored” handle and will hold about 8 pounds of clay. Find it at clay-king.com or other ceramic suppliers.

EX-115 4” Extruder

Another extruder with limited availability is the EX-115 4” Extruder. This model features a fixed lever, a round barrel, and square dies. Bailey or North Star dies will most likely work with this model. Find out more at clay-king.com.

Powered Extruders

If you have a production studio or just want an easier way to extrude, powered extruders are available. They are not the main focus of this article, but for more info check out these websites:

Bailey System 3 Power Drive, starts at $946 but you’ll need to order barrel, dies and other parts. See more at baileypottery.com

MudTools Push Extruder, $1,400. See more at mudtools.com.

Peter Pugger Hydraulic Extruder, $4999. See more at clay-king.com.

Extruder Tips

A few tips for getting the most out of your extruder.

Keep it clean! A clean extruder stays rust free and functional. You can put a light oil on moving parts to keep things functional.

For cleaning, get big blocks of clay out and if you have time, you can let other clay bits dry. Then knock them out and proceed with cleaning. It’s always easiest to clean completely dried clay.

Use the most moist clay you can as this will be easier to extrude. But, if you are working with bigger forms, stiffer clay can hold more structure right away.

Some people recommend spraying cooking oil inside extruders. I never do this for two reasons. 1) cooking oil can “gum up” if left sitting places and 2) while I do oil moving parts and hinges on extruders, there’s no need to mix any sort of oil with clay. Keep the barrel clean and use clay that is the right consistency, and it should be easy to extrude.

Let forms “hang” for a bit before cutting off. This will allow them to stiffen up and stay true to form, which is especially important as you move into hollow shapes that are 4 inches in diameter or more.

Protect your dies from being bent. Don’t over-push the lever or wheel as you can bend or ruin dies. If the machine won’t go any further, don’t push it.

For project ideas, check out the books Extruded Ceramics or The Extruder Book.

Wall Mounted Clay Extruder Comparison Chart

This chart is organized first by barrel size and then alphabetically by manufacturer.

| Model | Typical Price | Barrel Shape |

Barrel Diameter |

Barrel Material |

Capacity | Lever | Detachable Barrel |

Warranty |

|---|---|---|---|---|---|---|---|---|

| Bailey Standard 4 | $309-$387 | Square | 4" | Mild Steel | 11 lbs | Slide | No | 2 Years |

| Bailey Stainless 4 | $346-$433 | Square | 4" | Stainelss | 11 lbs | Slide | No | 2 Years |

| Brent STD | $574-$675 | Round | 4" | Mild Steel | 10 lbs | Slide | No | 1 Year |

| Brent HD | $548-$685 | Round | 4" | Mild Steel | 10 lbs | Slide | Yes | 1 Year |

| Clay Master | $350-$420 | Square | 4" | Stainless | 8 lbs | Fixed | No | ? |

| Crackpots | $199 | Round | 4" | Mild Steel | 7 lbs | Fixed | No | ? |

| EX-115 | $350-$400 | Round | 4.5" | Stainless | 7 lbs | Fixed | No | ? |

| North Star 4" Standard | $370 | Square | 4" | Mild Steel | 8-9 lbs | Fixed | No | Lifetime |

| North Star 4" Stainless | $440 | Square | 4" | Stainless | 8-9 lbs | Fixed | No | Lifetime |

| Scott Creek 4" | $399 | Round | 4" | Aluminum | 8-9 lbs | Stepped | Yes | 2 Years |

| Scott Creek 5" | $460 | Square | 5" | Aluminum | 12 lbs | Stepped | Yes | 2 Years |

| Bailey Standard 5" | $340-$426 | Square | 5" | Mild Steel | 17 lbs | Slide | No | 2 Years |

| North Star Big Blue | $950-$1090 | Square | 6" | Mild Steel | 25 lbs | Wagon Wheel | Yes | 2 Years |

| Bailey Standard 9 | $517-$647 | Square | 9" | Mild Steel | 29 lbs | Slide | No | 2 Years |

Summary

Wall mounted clay extruders are a great tool in the studio. The are the best way to make hollow forms, such as tubes, squares, hexagonal or custom shapes. Most models also include a test tile form, which can speed up that process. Overall, all the extruders above will be long-lasting and durable. They differ on size, die options, lever options, and material. Overall, my favorite is the North Star Big Blue Extruder as I find it the easiest and most practical to use. But a simple lever option, such as the Scott Creek, North Star, or Bailey, are also affordable and durable.

What is your favorite extruder? Let us know in the comments.