Kiln wadding is very useful for loading kilns, and this all-purpose recipe and tutorial shows you how to make it. This recipe includes the weight of water needed, so you get the consistency just right and can use the wadding right away.

Wadding has a variety of uses, such as making kiln shelves even, lifting pots off shelves, or to space lids in a glaze firing. Wadding can be used in any type of firing, including electric, gas, soda, or wood firings. If you are doing soda or salt firings, you may need a slightly different mix but this recipe is what I use in my studio for mid-range electric firings, and it’s the same recipe that I have used in the past in high-temperature gas firings.

The key for wadding is that it dries out quickly, and doesn’t stick to your kiln shelves or ceramic wares. Making it out of kaolin and highly refractory alumina oxide accomplishes these tasks.

This wadding recipe also includes the water needed. It can be very easy to add too much water when mixing wadding, and this recipe gets the consistency just right for wadding that can be used immediately.

Here’s the recipe:

All-Purpose Kiln Wadding Recipe

| Ingredient | Percentage | 1000g batch |

|---|---|---|

| Kaolin | 50 | 500g |

| Alumina Oxide | 50 | 500g |

| Mix in | ||

| Water | 25 | 250g |

Super simple, right? Just an even amount of two ingredients and then 25% water by total weight of the dry materials. Before testing and using this weight of water, I would estimate and always added too much water. Then, I would have to dry out the wadding before using. Note that this may seem like too little water at first, but it does work.

In my experience, about 1000g of dry materials will fill a large, 32oz sized deli or yogurt container. If you don’t use wadding frequently, you can make a smaller batch or also keep it in a plastic bag inside a container. It’s also ok to add water from time to time to maintain your wadding in a workable state.

For more info, check out the tutorial below with pictures.

How to Mix Kiln Wadding Tutorial

This tutorial shows how to mix the above recipe, to end up with wadding that you can use immediately. This tutorial shows how to mix 500g of dry materials, which ends up with enough wadding to fill a 16 oz plastic container. 1000g of dry material will usually fill up a 32oz deli or yogurt container.

Before starting, be sure to gather your scale, materials, water, and put on a good quality dust mask or respirator. (Read our guide to respirators here)

Step 1

Kaolin being weighed.

In this tutorial, 500 grams of total dry material will be mixed.

To start, weigh 250g kaolin. EPK was used in this recipe, but you can use any kaolin.

Place kaolin in a bucket for mixing, such as a wide Big Mouth Bucket as pictured below.

(Shop bucket at Home Depot | Shop at Amazon)

Step 2

Weigh 250g alumina oxide, and then add it to your mixing bowl.

Step 3

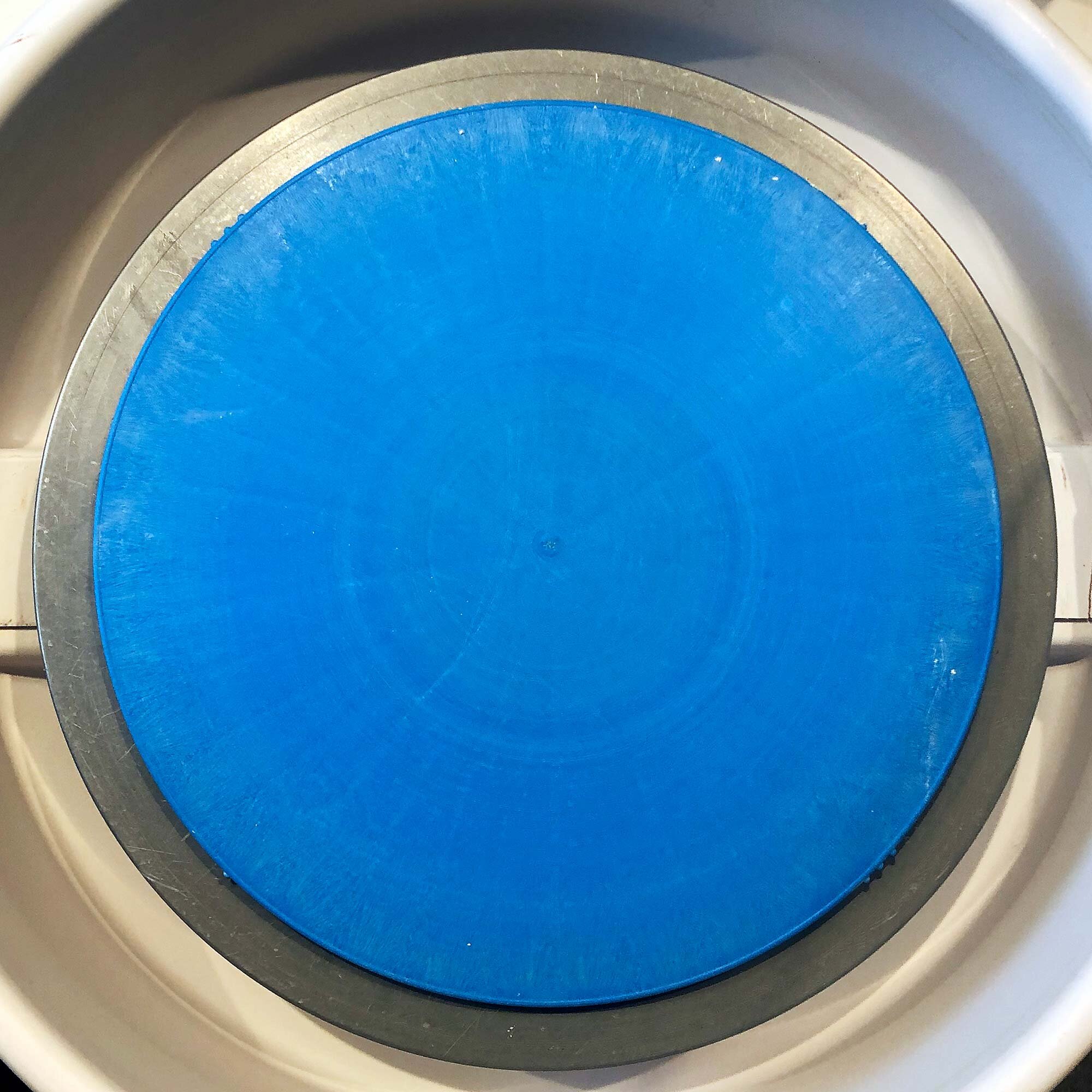

Kaolin and alumina oxide added to a bucket.

Mix the dry ingredients. It is important to do this before adding water, so that the materials are evenly dispersed.

The kiln wadding ingredients after mixing. The metal scoop was used to stir the ingredients.

A wide bucket, such as the 5qt Big Mouth Bucket, are great for this process.

Step 4

Weigh the water. For 500 grams of dry material, 125g of water is needed.

It may not seem like enough but it will be!

Step 5

Adding water to the dry materials.

Add the water to the dry materials, and mix. This wadding will be crumbly, but that’s ok.

Usually, I add dry materials into a bucket with the water, but for wadding it is ok to mix it either wet into dry, or dry into wet.

The mix will be crumbly at first.

With a bit more mixing, all the dry material starts to hydrate.

Step 6

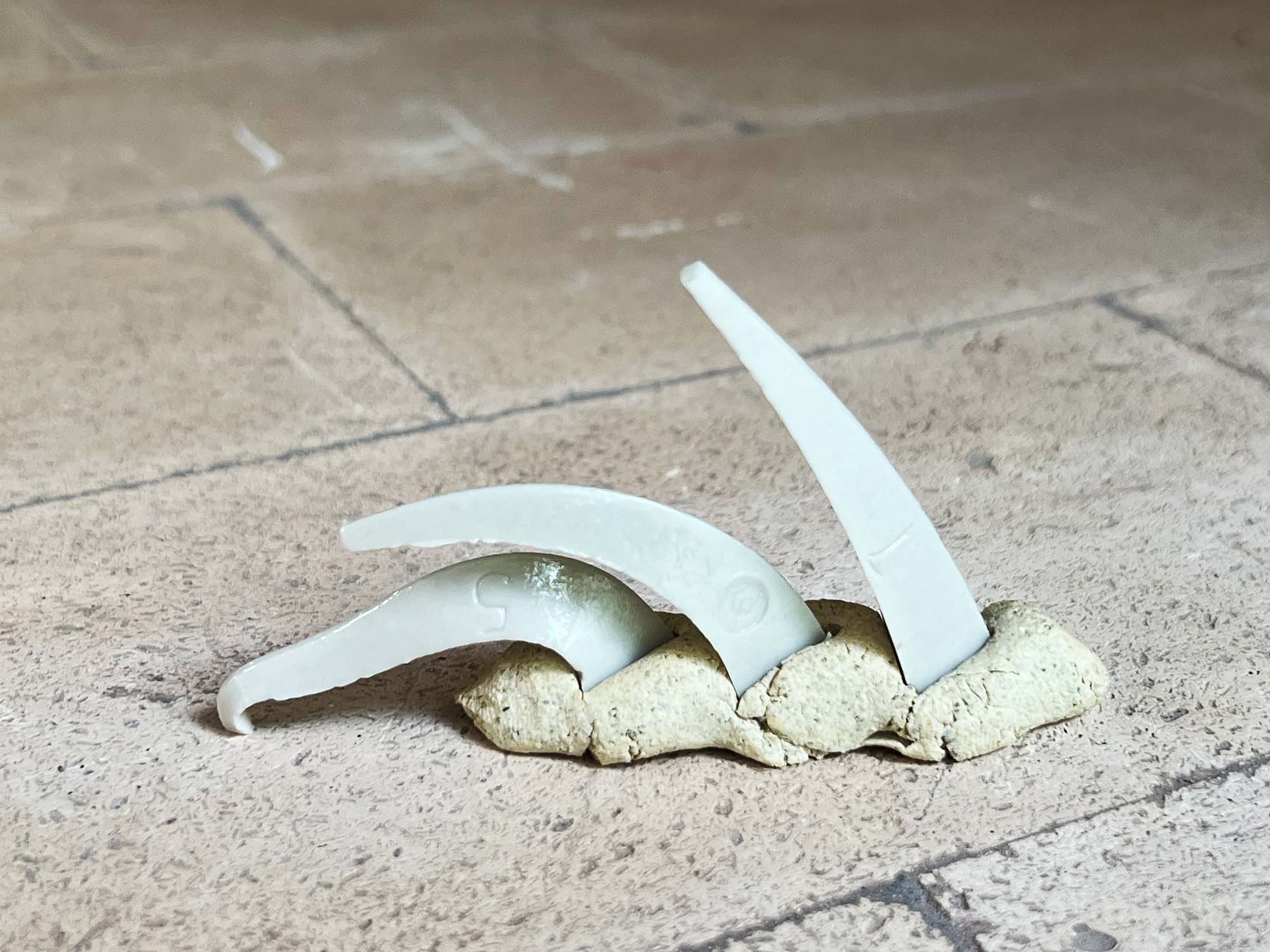

Kiln wadding after mixing but before wedging.

The next step is to move the mixed material to a wedging table. It will be a bit crumbly. Then, wedge until fully mixed.

When all the materials are wet and your wadding seems usable, you are done.

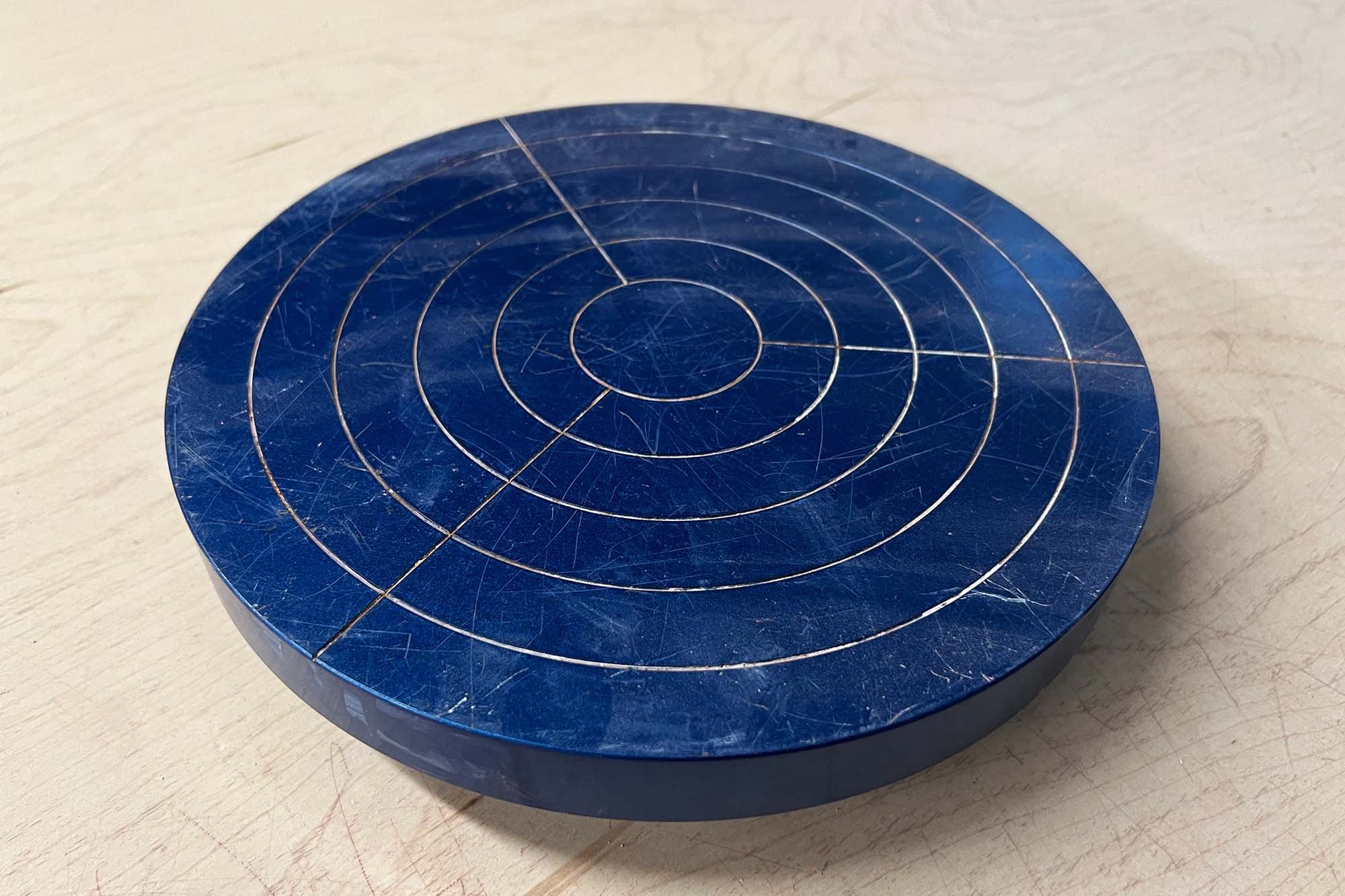

Kiln wadding after wedging. Ready to use or put into a storage container.

Place your wadding in a plastic container. You can also line the container with a bag, to keep it wet.

Step 7

500 grams of dry material will result in kiln wadding that uses about half of a 32 oz yogurt container.

Your wadding is now ready to use or store.

Your wadding is now ready to use. Be sure to label your container.

Conclusion

This post has covered how to mix and make kiln wadding. The key is to just add 25% of water by weight to the dry materials, so that you end up with a useful wadding right away.

What wadding recipe do you use? Let us know in the comments.

You may also enjoy:

Best Scales for Ceramic Studios