Lucie Rie by Tony Birks is the definitive monograph on the Austrian-British potter. The book contains numerous color and black and white images of Rie’s work, along with a complete biography and history of her work. It also includes a chapter on Rie’s technique and ways of working. First published in 1987, the book has been reprinted numerous times. Currently it appears to only be available used in hardcover or paperback.

The cover page of Lucie Rie by Tony Birks

Born and raised in Austria, Rie later moved to Great Britain in the 1930s. In London, she set up a studio and became acquainted with British potters such as Bernard Leach. Later, Hans Coper began working in Rie’s studio, and eventually the two collaborated on production ware before Coper set off on his own. Throughout, Rie maintained a focus on the wheel thrown vessel that was informed by her early influences such as the Wiener Werkstätte and other forms of modern art. Her pieces, however, maintained a handmade touch, exquisite glazing, and lots of fine line and scraffitto work.

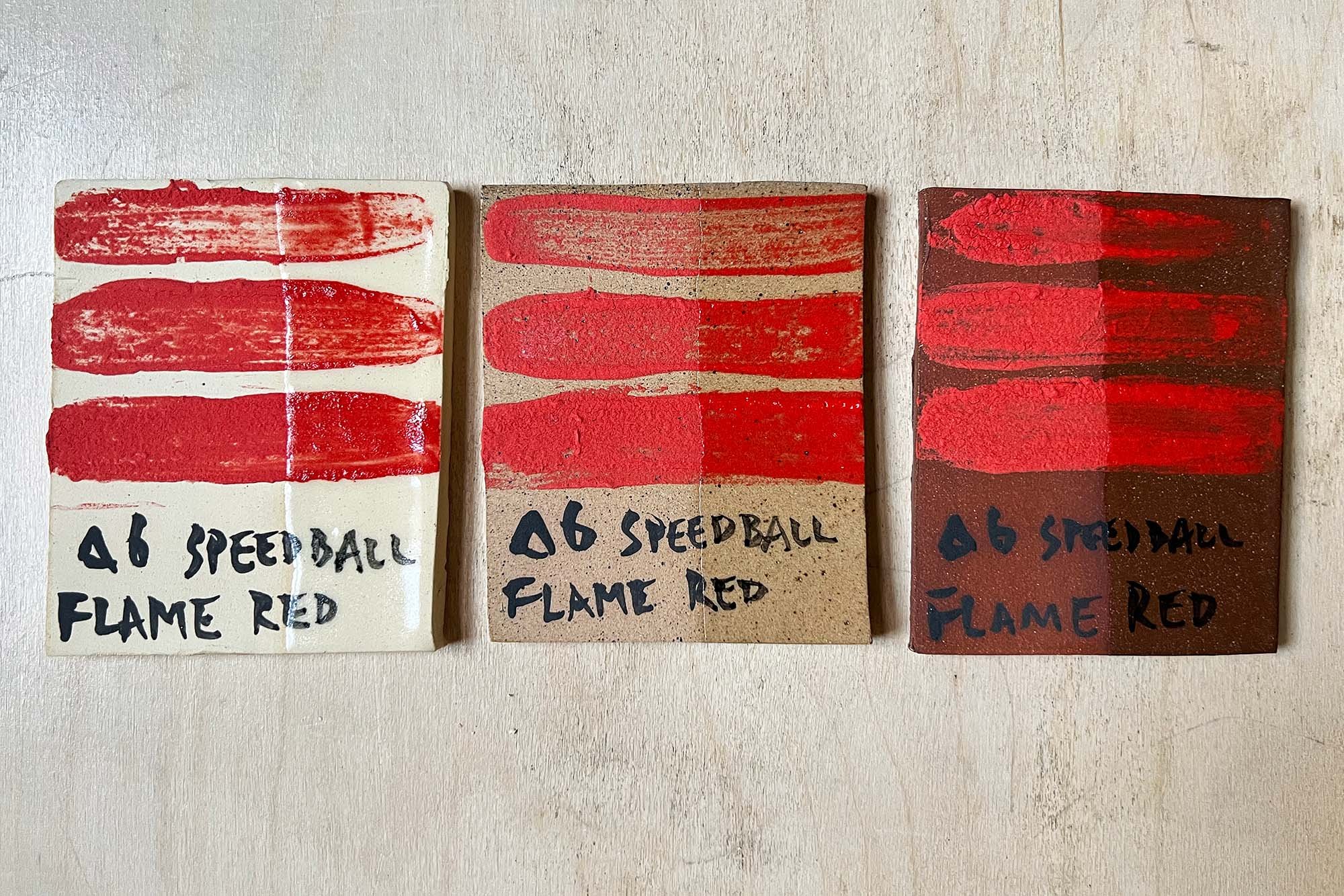

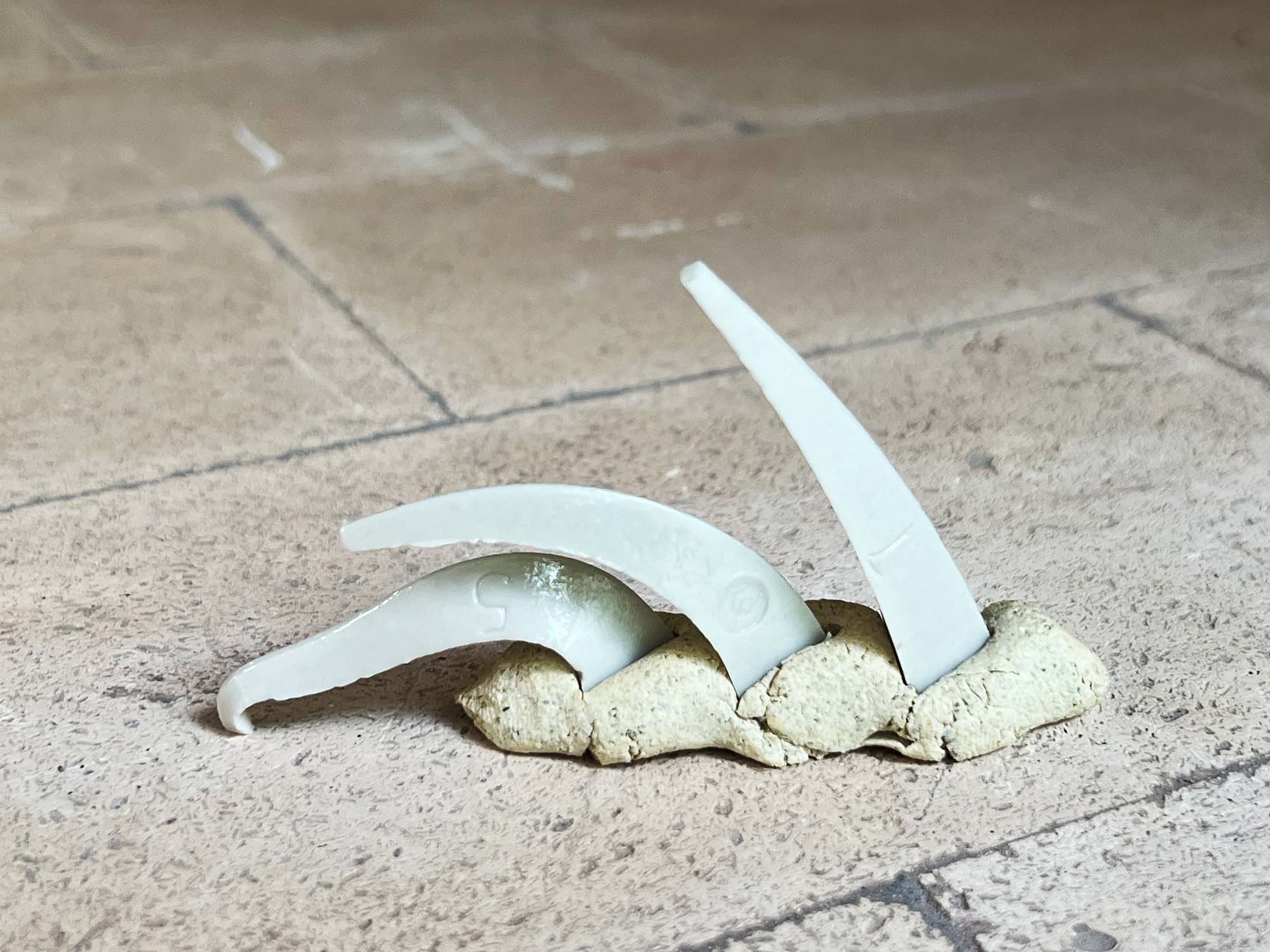

In a section on technique, Birks details the various methods of making and firing the Rie employed, which included single-firing her pots in an electric kiln to cone 8, along with very fine scraffitto work done with a needle tool while pieces were bone dry.

Overall, this book is a must-have for any potters or fan of ceramics, as it gives a deep insight into Lucie Rie, one of the most prominent potters of the 20th Century.

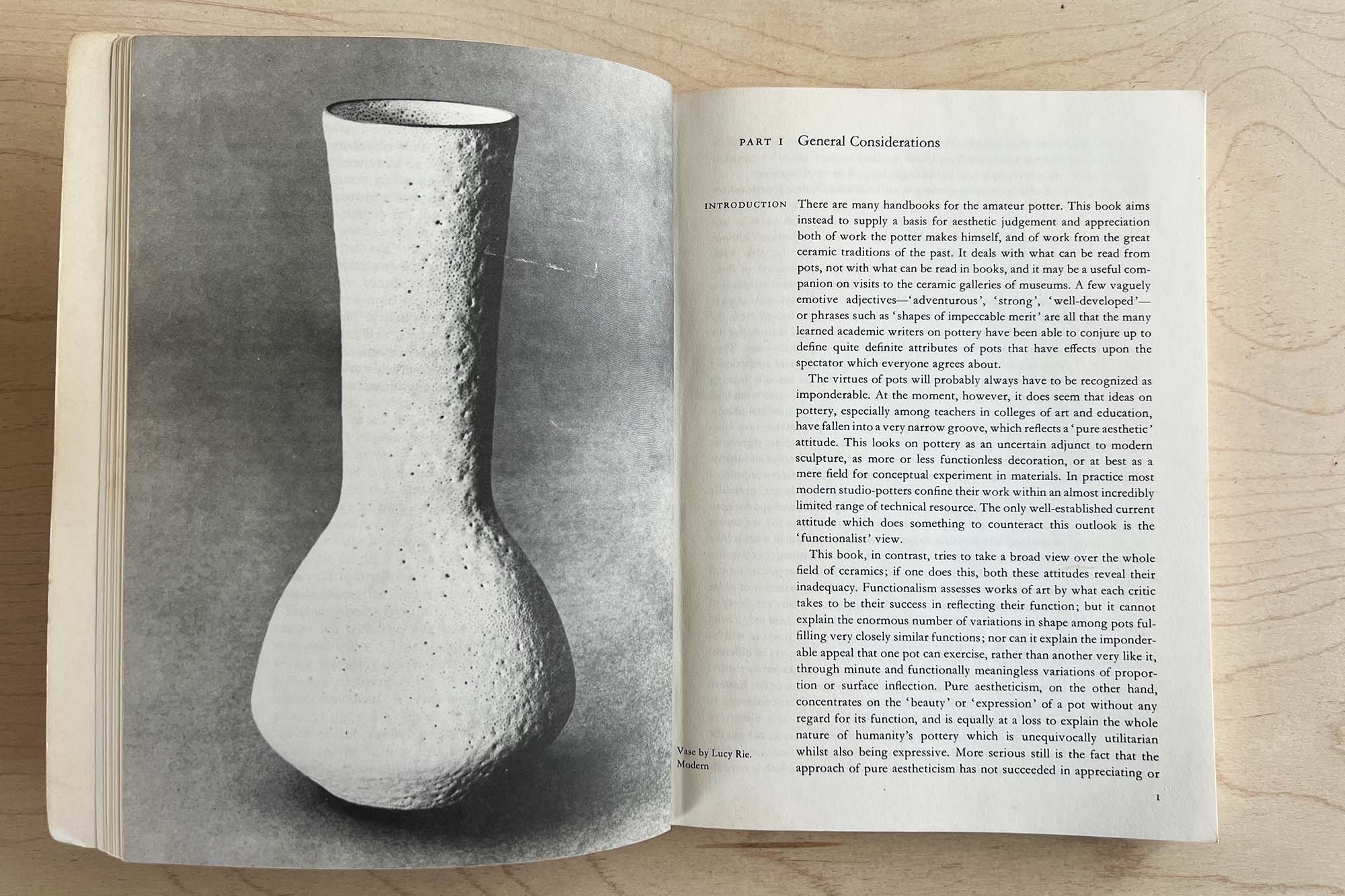

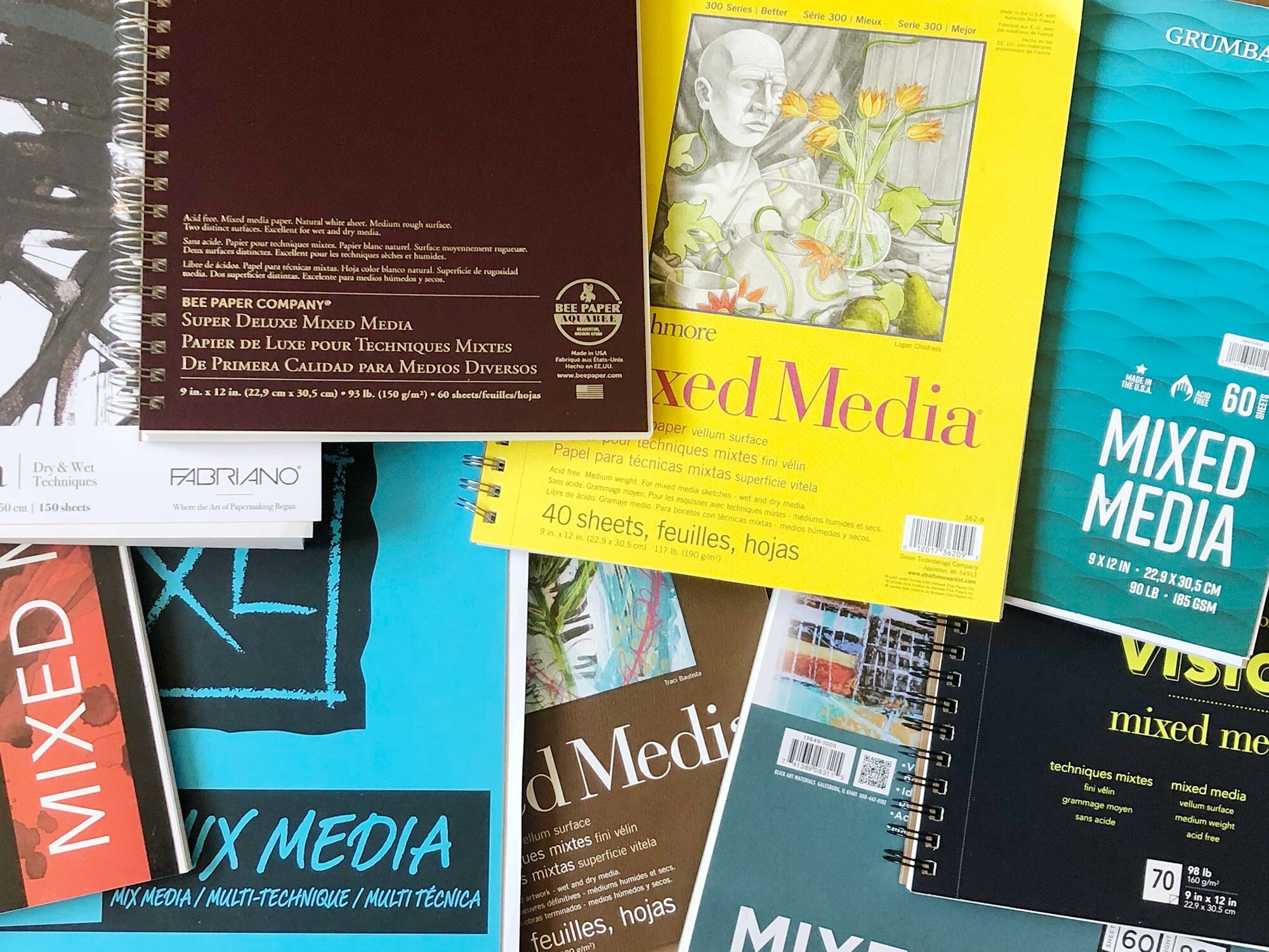

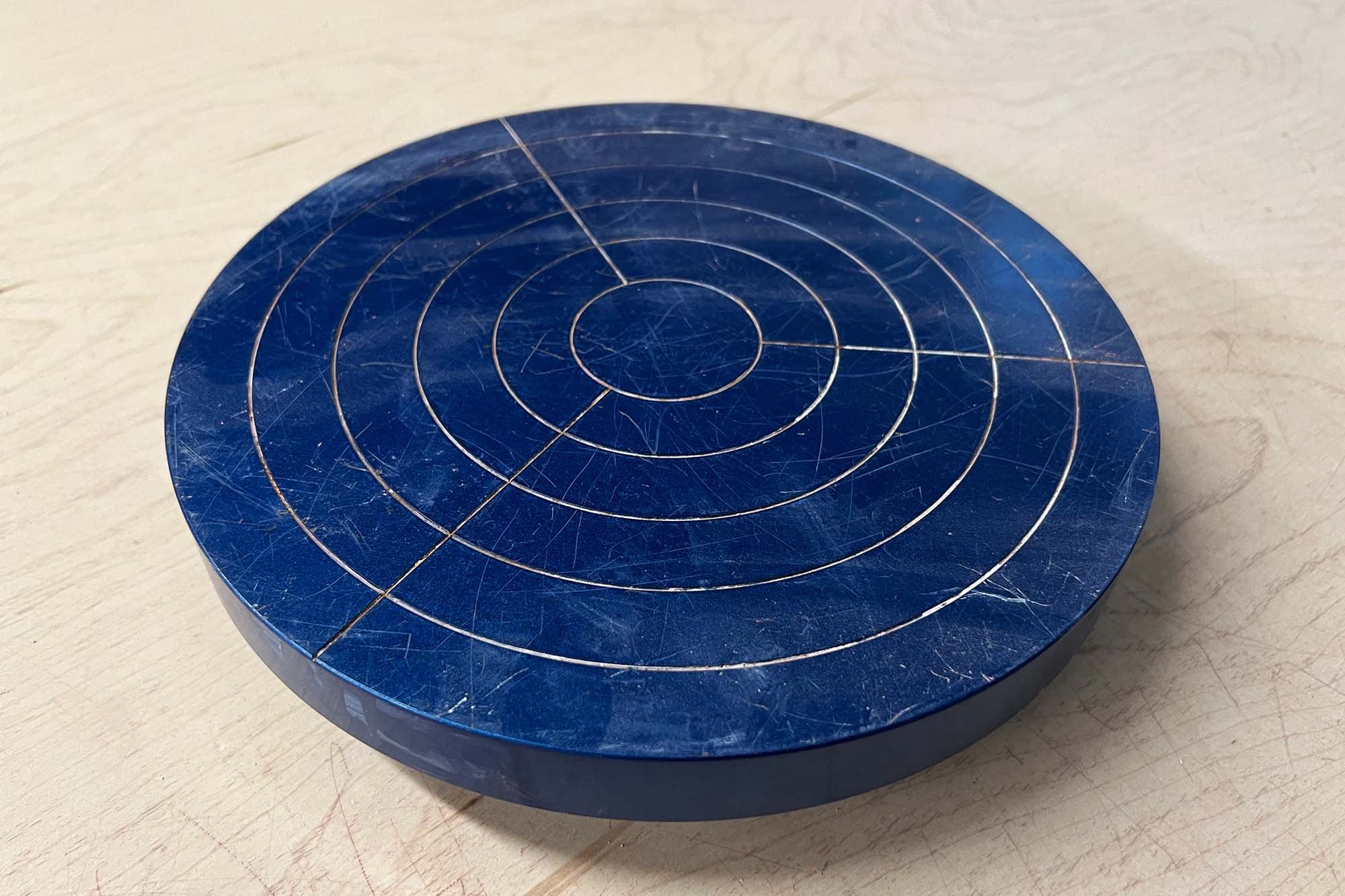

Images from the book

A spread with three bowls illustrating Rie’s superb glaze technique.

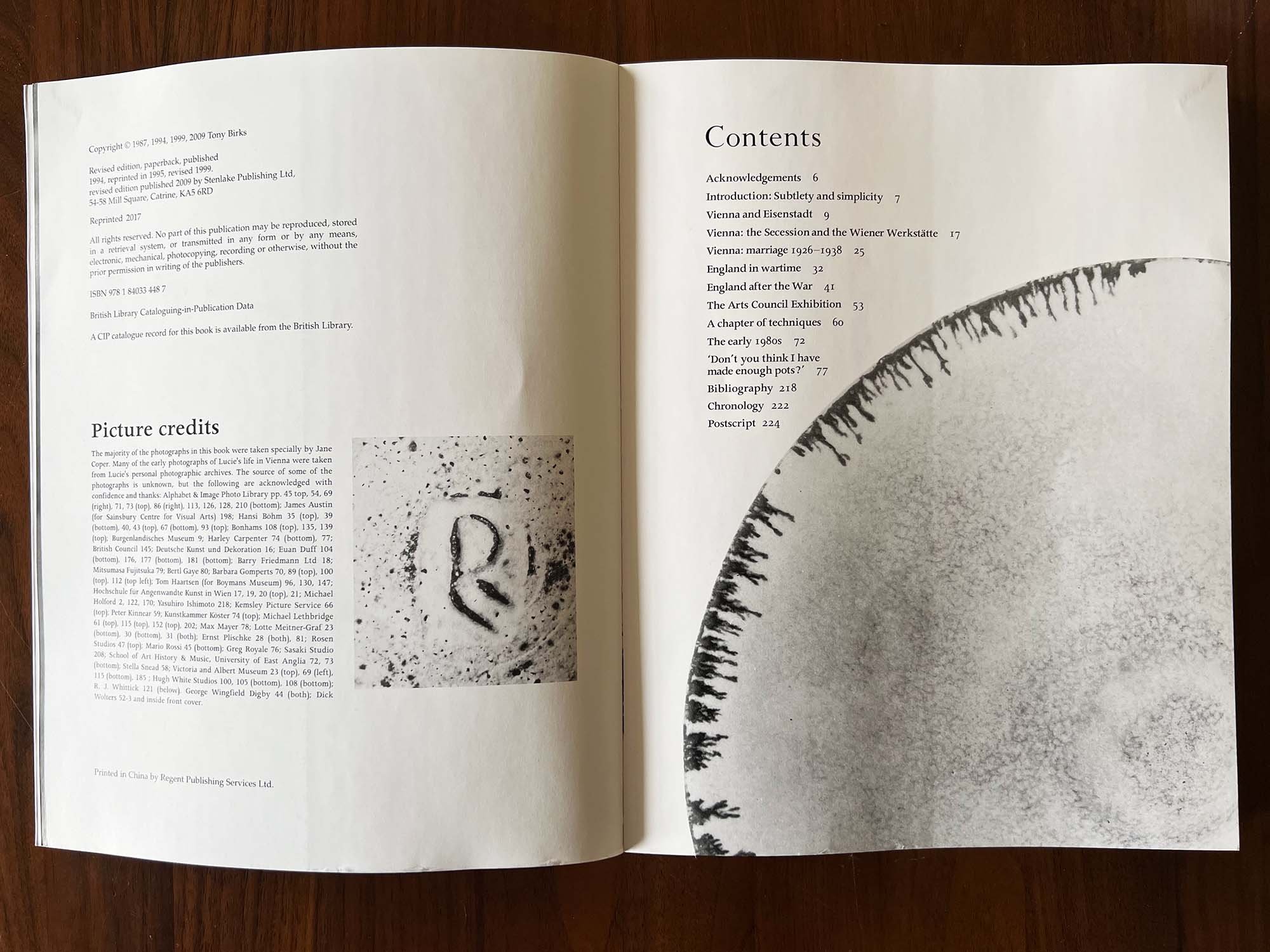

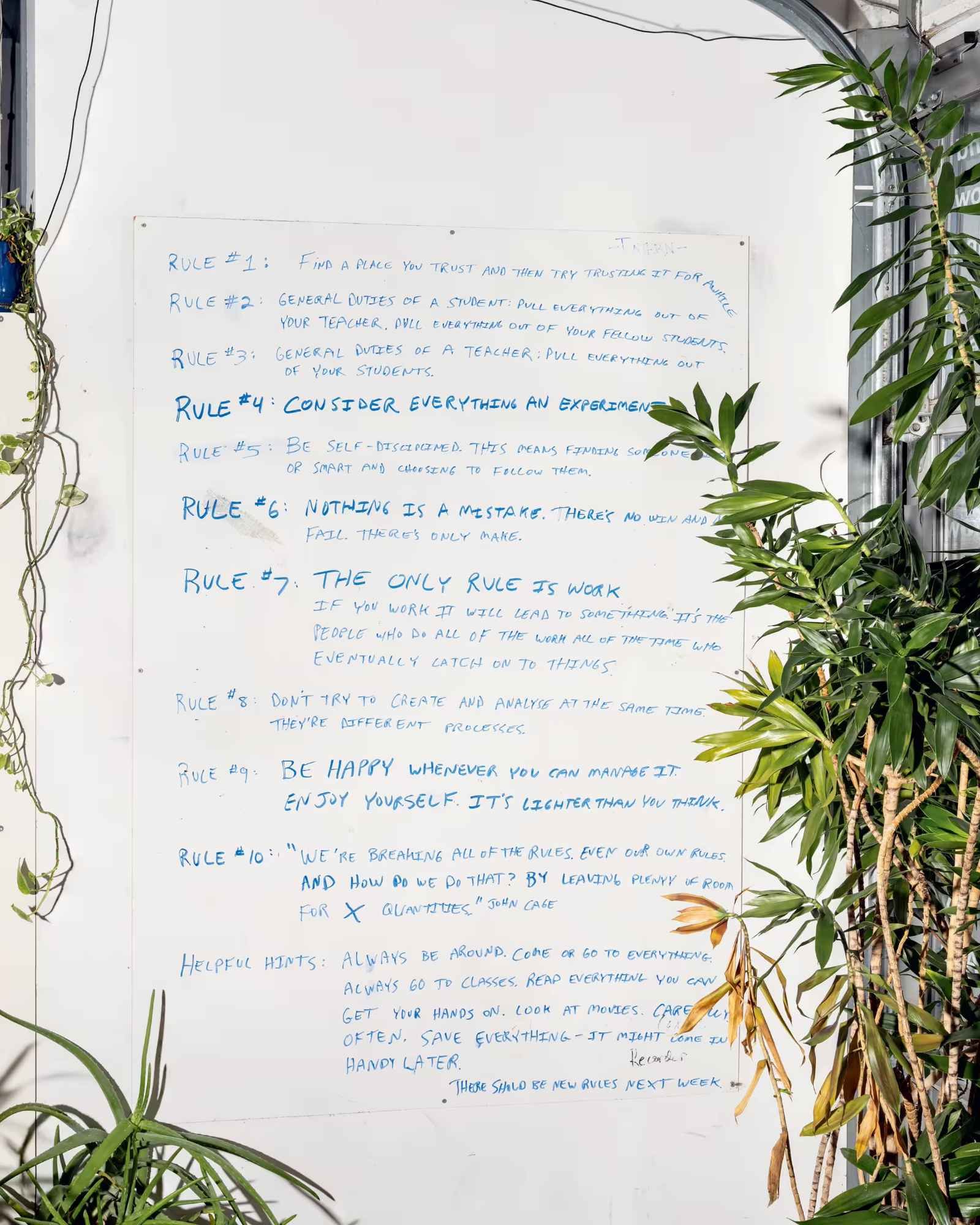

The table of contents

The image at the upper left is Rie with Hans Coper. At right is Rie with Bernard Leach.

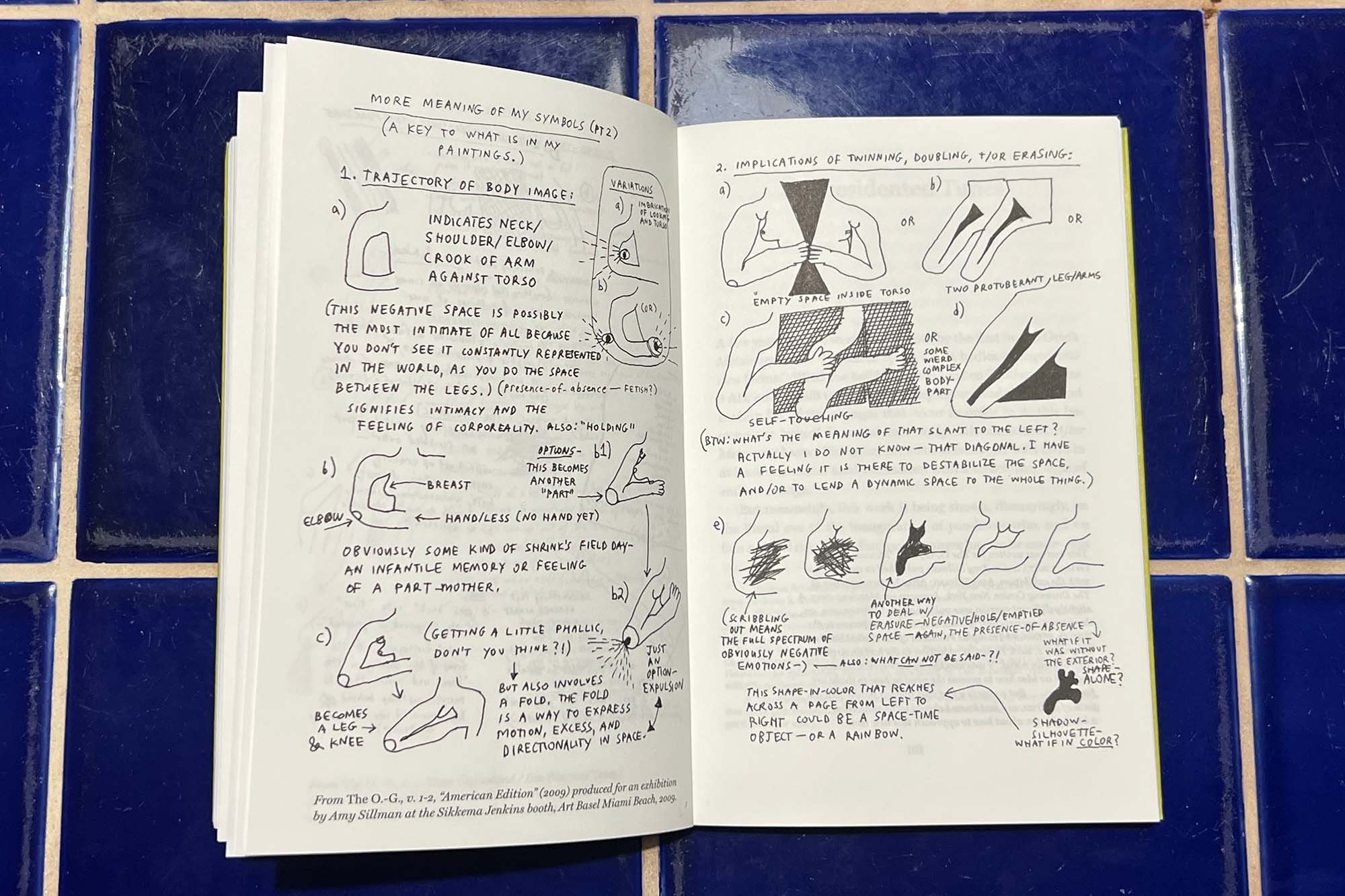

The revelatory chapter on techniques Rie used to make her vessels.

You might also enjoy:

Roger Herman Ceramics monograph

A Potter’s Workbook by Clary Illian

What are your thoughts on Lucie Rie by Tony Birks? Let us know in the comments